Finishing Processes

PROCESSING > FINISHING PROCESSES

FINISHING PROCESSES

Constantly at the cutting edge of technology

We can process workpieces made from all kinds of materials and alloys – in a productive, cost-effective and environmentally friendly way. We are known around the world as a specialist in surface processing. We change, improve and anneal your products to give you long-lasting quality. Over the years, mass finishing has developed into a broad range of processing types.

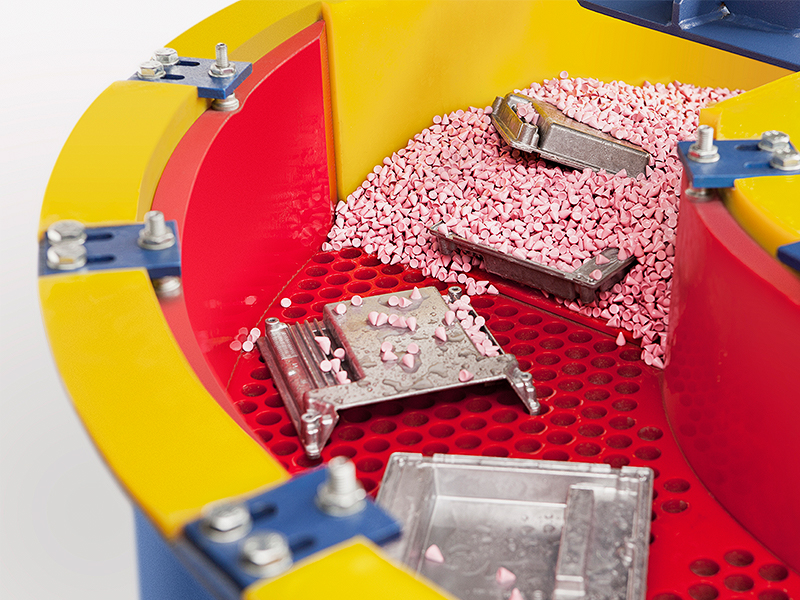

DEBURRING

Whether casting, stamping, sawing or machining, virtually every shaping process leads to burrs that can vary greatly in shape. These burrs can be difficult to remove, especially on angled workpieces.

GRINDING & BLENDING MACHINING LINES

Walther Trowal’s mass finishing equipment is capable of grinding and blending out CNC machining lines visually shown in a machined part. This is accomplished by utilizing the energy being generated in mass finishing piece of equipment and the abrasive media flowing over the surface of the parts.

SMOOTHING SURFACES & Ra REDUCTION

There are lots of reasons that favour smoothing workpiece surfaces, such as aesthetics, lower friction or air resistance, lower wear, quieter running, and many more. These apply whether your surfaces are made from metal, ceramics, plastic, wood or other materials.

SURFACE POLISHING

Do you need to polish your decorative parts, fittings or other surfaces to a glossy finish? Doing so by hand is costly and time consuming. Our trowapast process is an extremely effective alternative to manual polishing in both a technical and economic sense.

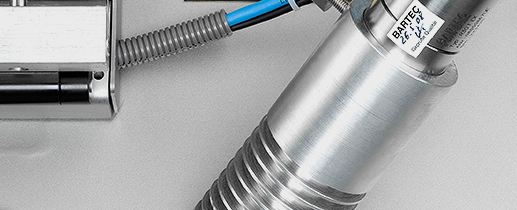

CLEANING & DEGREASING

When materials are stamped, sawn or reshaped, cooling is usually achieved using oil-based lubricants. These usually need to be removed in degreasing baths in an intermediate step prior to further processing. Machine parts often require thorough cleaning before being reinstalled. This is particularly true of companies in the automotive or mechanical engineering sectors, as well as for workshops and maintenance service providers.

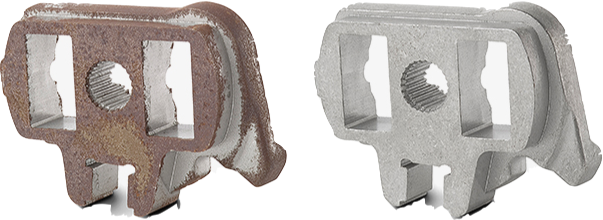

PICKLING & DESCALING

As well as burrs and sharp edges, trowalizing also removes scaling, rust and annealing colours. We can process complex, angled parts with special acidic or alkaline compounds. Even indentations and open pores can be made bright and optically attractive, whilst also saving time and costs.

BLASTING

You can use our blasting technology to process your surfaces quickly, simply and with the utmost precision. Our THM conveyor blasting units are perfect here. Whether you are roughening, cleaning, deburring or removing deposits, they provide excellent results for both bulk material and complex, sensitive parts.

COATING

Our decorative and functional surfaces can better protect your workpieces against friction, prevent slipping, improve grip or resistance, make them smoother, or give them a matt or glossy finish.

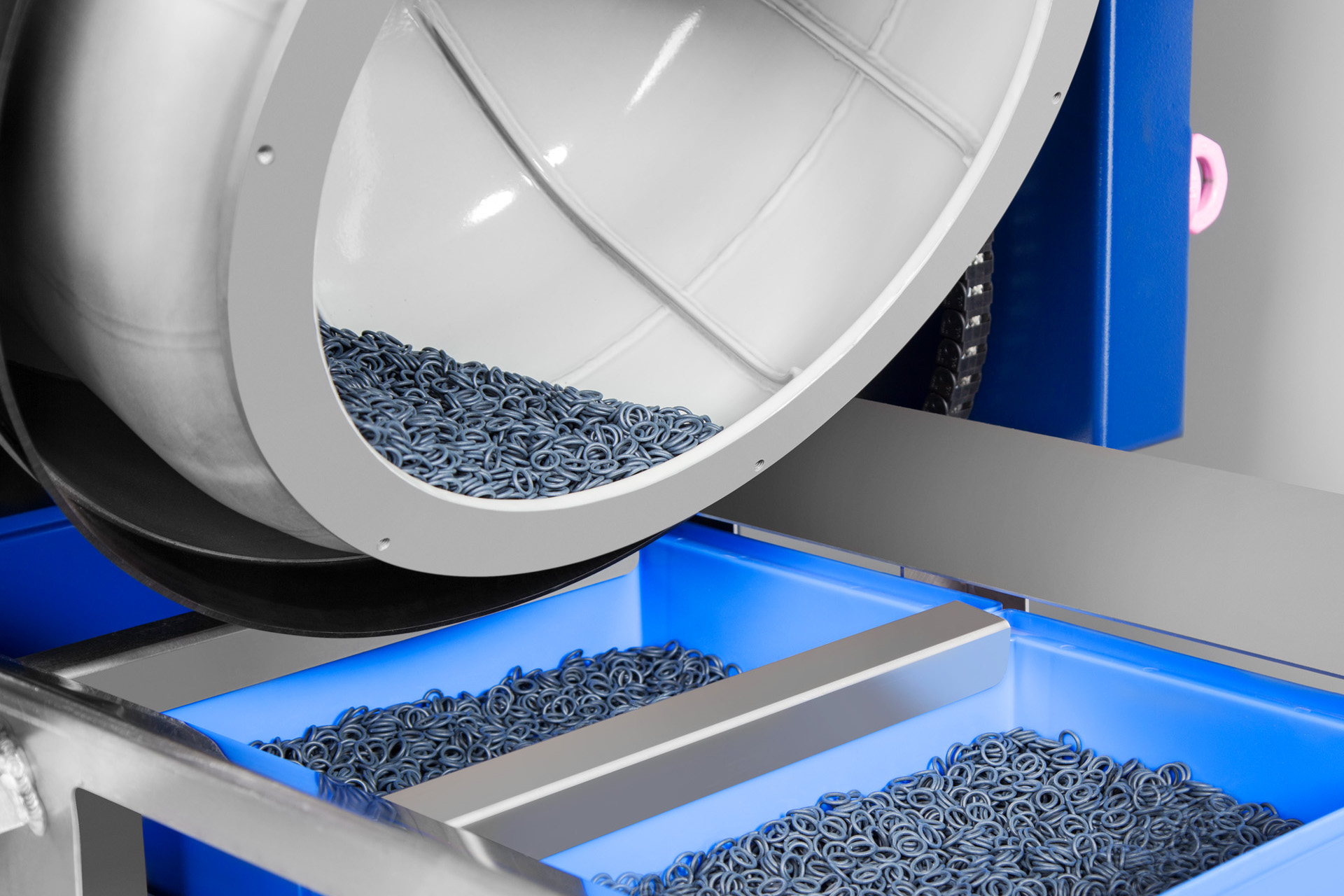

EDGE BREAK & RADIUSING

Parts with rounded edges slide on and in each other more easily. One example of this is the clip on a car seatbelt. Rounded edges also reduce the risk of injury.