Process Water Recycling

Recycling Of Your Process Water Or Going To Drain?

Whenever they are investing in a new mass finishing system, customers must always decide on how they want to handle the process water from their finishing operation. This column is intended to provide some pointers as to whether recycling of the process water or sending it to drain represents the better alternative. The answer to this question is quite easy: It depends on the respective mass finishing application.

Process water recycling: Proven in numerous applications

During mass finishing operations the process water gets contaminated with fines from the work pieces and media and, occasionally, oil and grease carried into the finishing machines. Before it can be returned to the mass finishing process or sent to drain, the process water must be cleaned.

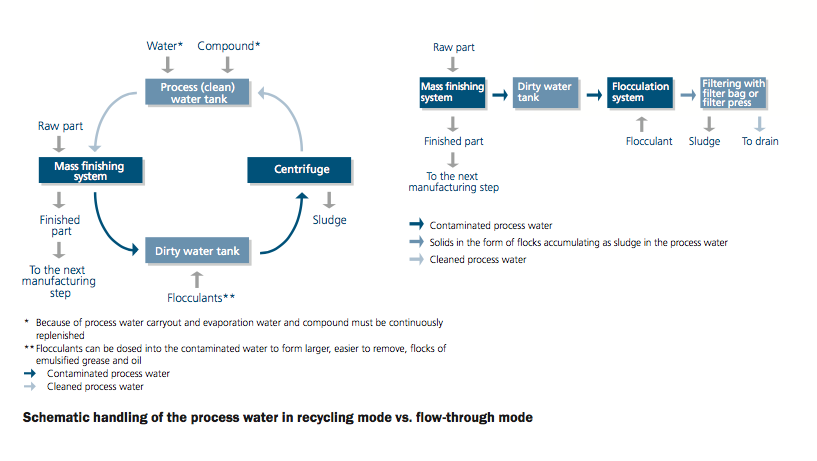

For about 80 to 90 % of all mass finish- ing applications cleaning of the pro- cess water and recycling it back to the finishing process represents the most suitable and economical alternative: In a closed loop system the process water is continuously cleaned and returned to the finishing equipment. This helps not only to drastically reduce the water consumption but also saves compound. In recycling systems up to 90 % of the utilized compounds can be

re-used in the finishing operation. An additional advantage is that the users do not require a permit from the water authorities. And finally, because recycling systems produce a lot less sludge, the expenses for sludge disposal will be lower. Overall, recycling of the process water results in a more eco-friendly and cost-efficient operation with, at the same time, excellent surface finishes on the work pieces

Flow-through systems: For especially demanding finishing applications

Although it offers many benefits, recycling of the process water is not always possible. For example, this is the case when…

• …the surface of the finished work pieces must be exceptionally clean,

• …a mass finishing process requires multiple stages with different compounds,

• … acidic or alkaline compounds are utilized.

For such applications so-called flow- through systems – cleaning of the pro- cess water by flocculation and sending the cleaned water to drain – represent the by far simplest, safest and most economical water treatment method. Especially in the automotive and machinery building industry the demands for excellent surface finishes and work piece cleanliness are particularly strict. For example, this is the case with components for transmissions and fuel injection systems, decorative components in the passenger compartment as well as bearing parts and linear guide systems. After the mass finishing operation the cleanliness of all these components must be such that prior to assembly they do not need to undergo an additional cleaning operation. The customers in these industries expect ready-to-install components that can be further processed or installed without having to go through another cleaning stage.

Crystal clear conditions

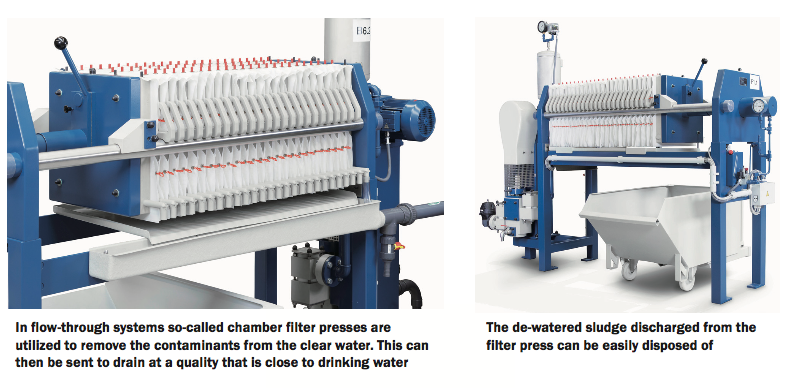

In mass finishing operations with flow- through systems the process water comes directly from the public water supply network. After it has been used in the mass finishing process, the contaminated water is cleaned in a water treatment plant. There special flocculants combine the contaminants in the process water, such as metal and media fines as well as oil and grease, into larger flocs, which are sinking to the bottom of the respective treatment tank in the form of sludge. Subsequently, this sludge is passing through a chamber filter press to reduce its water content. The sludge cake coming from the filter press can then be disposed of as normal waste. After having passed through the treatment plant the cleaned water is crystal clear and can be sent to drain in full compliance with all legal environ- mental standards.

Multi-stage finishing processes

In flow-through systems the process water is passing through the mass

finishing machine only once. There- fore, such characteristics like foaming or cleaning intensity can be precisely adapted to the respective mass finishing application. Besides water only small amounts of special compounds and additives are required to control the finishing process.

In flow-through mode it is also possible to successively inject different compounds into the mass finishing machine. This ensures that for the different phases of a finishing process the most suitable compounds can be utilized. For example, in case of very oily work pieces a high initial dosage

of degreasing compound is required that can be reduced during the next finishing step. For the last minutes of the process a compound can be added that offers excellent protection against corrosion.

Passing an audit with flying colors

The flow-through method is also preferable, whenever strict demands for process stability must be met: The water from municipal distribution systems has a consistently high quality and constant temperature. This allows running mass finishing processes at

extremely stable operating conditions … an important aspect, for example, for operational audits.

A practical example

A customer, operating multiple mass finishing machines, was initially using a recycling system, because it represented the most economical solution for the work piece mix existing at the time the machines were installed. Over time, with the growing work piece diversity and more demanding cleanliness requirements the customer had to change his operation from process water recycling to flow-through mode. Using the process water only once and sending it to drain after cleaning it in a treatment plant, proved to be more advantageous. Besides a higher degree of work piece cleanliness it also offered more operational flexibility and a higher cost-efficiency.

Today, for his 20 mass finishing ma- chines this customer is utilizing a flocculation system that cleans up to 70 m3 of process water per day. An essential characteristic of this water treatment plant is a special “cone hat”, a cone that separates the waste water collection zone from the clear water zone. This technical feature reduces the required treatment time considerably, because only a portion of the process water must pass through the filter press.

A clear focus on the environment

In the beginning some customers perceived the “high use” of fresh water and compounds as expensive. In fact, the flow-through mode is also quite cost-efficient. The fresh water that is continuously flowing to the finishing machine is not “consumed”. It is just “borrowed”, because upon completion of the process it is returned into the pool of fresh water. Both systems, be it the recycling mode or sending the cleaned process water to drain, represent a sort of recycling method. In each case a clean environment is the undisputed winner.

Good Vibrations

by Christoph Cruse Contributing Editor MFN

and General Sales Manager at Walther Trowal GmbH & Co. KG

Tel. +49.2129.571 207

: c.cruse@walther-trowal.de