TT…B CENTRIFUGAL DISC FINISHING UNIT

MASS FINISHING TECHNOLOGY > CENTRIFUGAL DISC FINISHERS

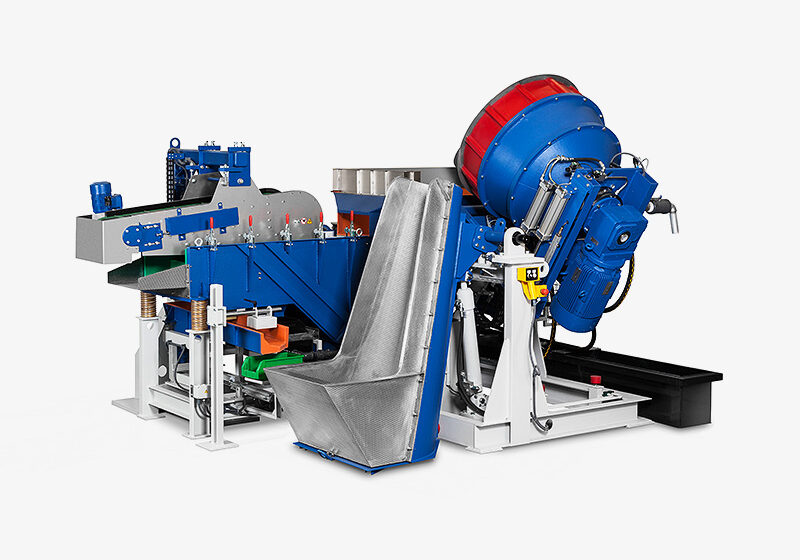

INDIVIDUAL SOLUTIONS

If you are searching for a custom solution for your mass finishing processes, the TT...B series is the best choice. The modular system allows you to fit the individual machines with feeders, screening machines and abrasive media return transport systems as required.

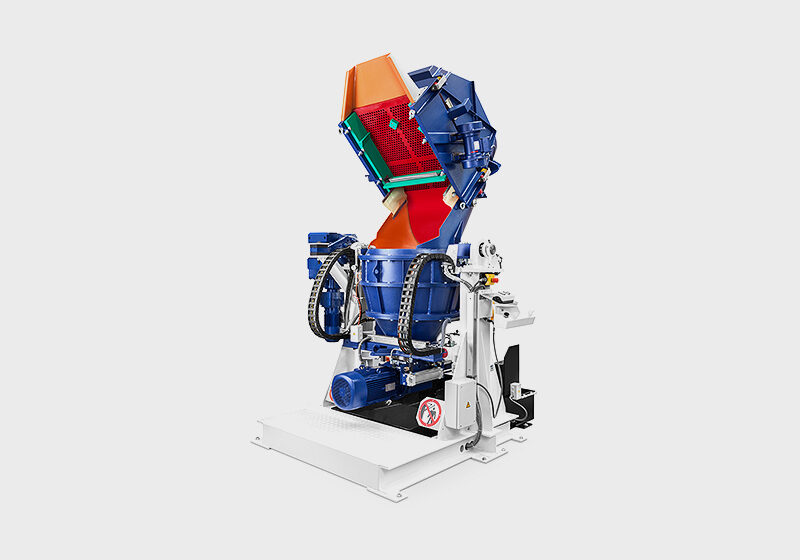

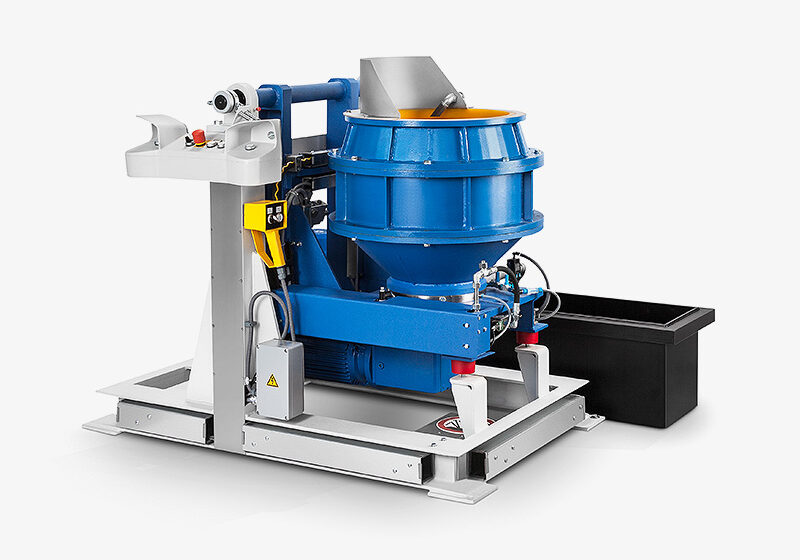

ELECTROMECHANICAL OR HYDRAULIC SYSTEMS AVAILABLE

The work bowl can be pivoted either electromechanically (TT 25, TT 45) or hydraulically. You can also partially automate processing with the respective peripheral devices such as feeding and separating units.

THE BENEFITS AT A GLANCE

- High productivity thanks to two-batch principle

- Minimized auxiliary process times

- Perfect for automated processes

- Save time, space and cost

TECHNICAL SPECIFICATIONS

| Machine type | TT 25 | TT 45 | TT 60-B | TT 90-B | TT 140-B |

|---|---|---|---|---|---|

| Gross volume (l)* | 25 | 45 | 60 | 90 | 140 |

| Usable volume* (l) | 3–18 | 5–28 | 6–40 | 8–60 | 14–100 |

| Work bowl material | Polyurethane | Steel / Polyurethane | |||

| Drive mode | electric | ||||

| Spinner power (kW) | 1,5 | 2,2 | 4 | 4 | 11 |

| Speed (RPM) at 50 Hz | 235 | 235 | 213 | 213 | 178 |

| * Part geometry, material and delicacy are important for the determination of the media/workpiece ratio. | |||||

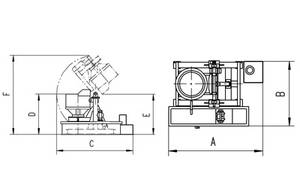

MEASUREMENT TABLE TT 25 AND TT 45

| A | B | C | D | E | W max. | |

|---|---|---|---|---|---|---|

| TT 25 | 1050 | 630 | 1400 | 430 | 480 | 135 ° |

| TT 45 | 1025 | 770 | 1525 | 470 | 500 | 120 ° |

| Dimensions in mm | ||||||

MEASUREMENT TABLE TT...B

| A | B | C | D | E | F | |

|---|---|---|---|---|---|---|

| TT 60-B | 2000 | 1370 | 2100 | 1070 | 1180 | 2180 |

| TT 90-B | 2000 | 1370 | 2100 | 1120 | 1110 | 2180 |

| TT 140-B | 2250 | 1700 | 2450 | 1260 | 1270 | 2500 |

| Dimensions in mm | ||||||