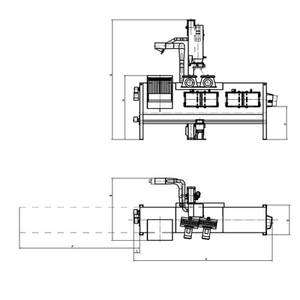

THM CONTINUOUS BELT BLASTING UNIT

MASS FINISHING TECHNOLOGY > SHOT BLASTING TECHNOLOGY

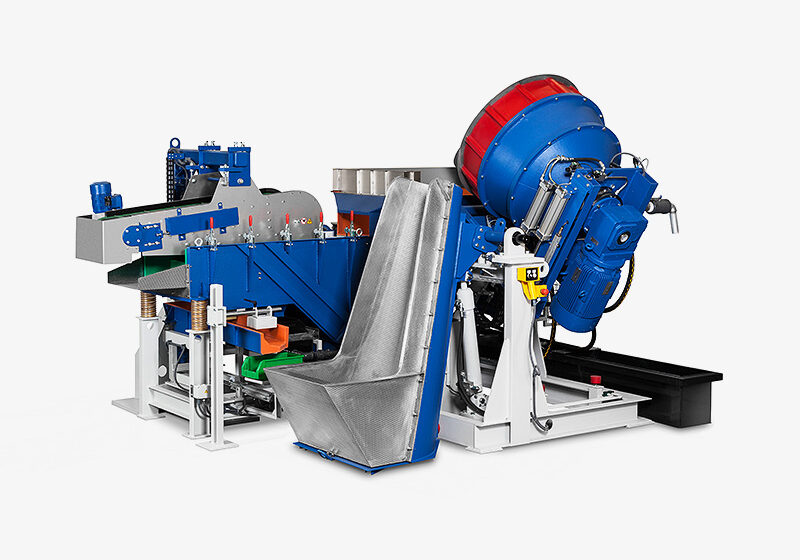

OUTSTANDING BLASTING RESULTS WITH A SMART TRANSPORT SYSTEM

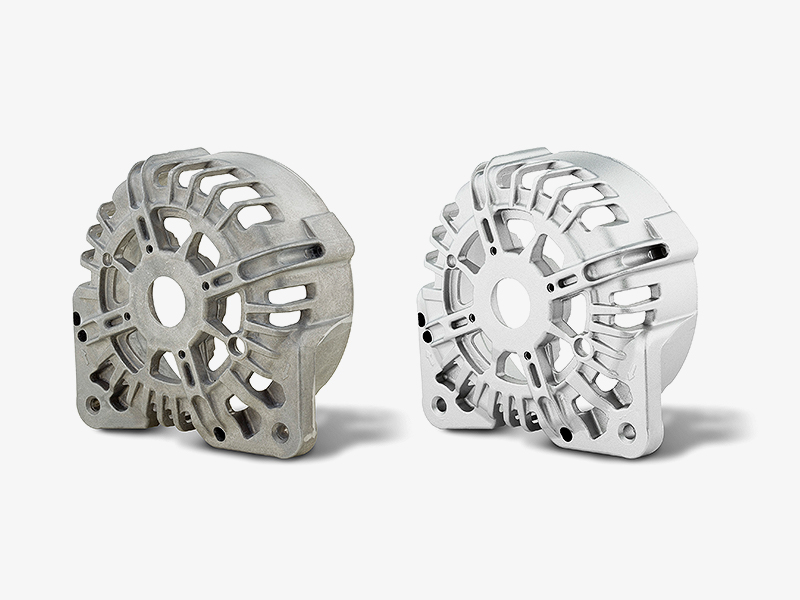

To help you get the most from continuous blasting technology, we have developed a system that sets high technical standards. The belt transport system conveys your workpieces evenly through the blasting unit, where they are continuously circulated and intensively blasted. This is an effective but sensitive way to process your workpieces.

SUITABLE FOR DIFFERENT WORKPIECE SHAPES AND SIZES

The THM conveyor blasting unit is a truly universal system, which allows you to process both bulk material and complex, sensitive individual parts. You can even use it to blast thin-walled workpieces. Even the rods on the belt are adapted to your workpieces. We use polyurethane for handling sensitive parts and manganese steel for standard workpieces.

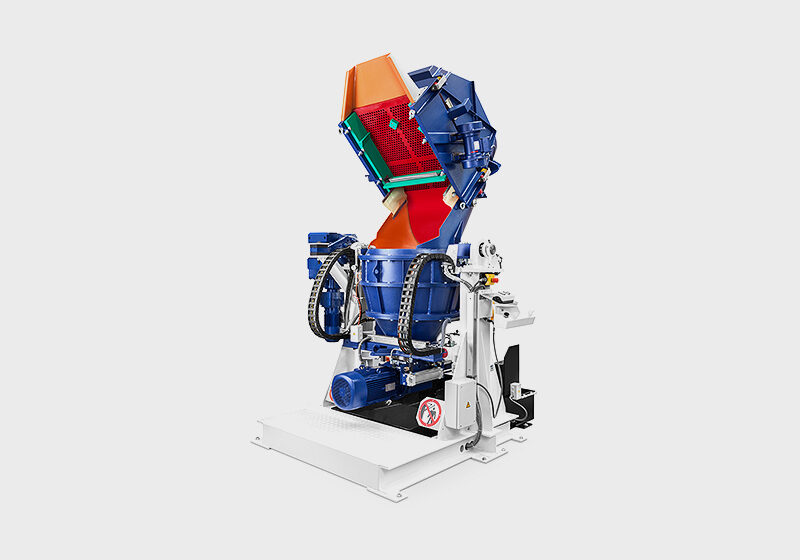

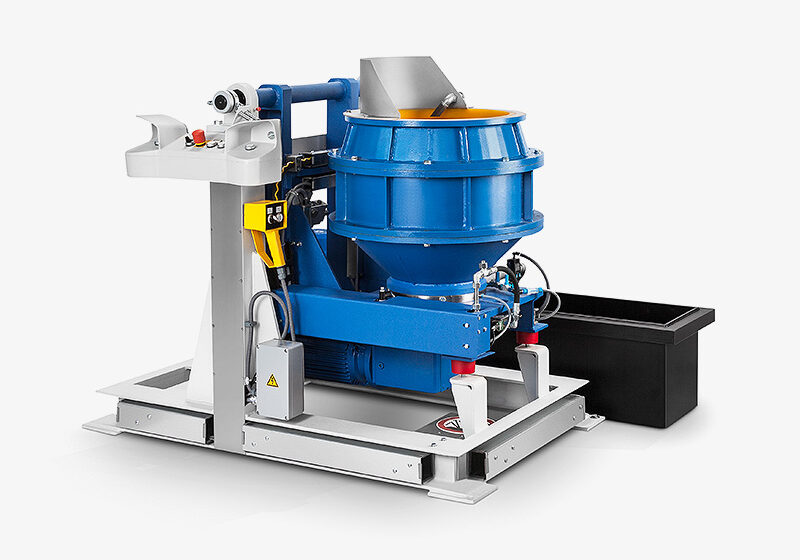

RAIL SYSTEM ENSURES QUICK AND SIMPLE MAINTENANCE

Thanks to an innovative rail system, virtually all wear zones on your workpieces are accessible. The transport system can be easily pulled out from the unit housing. This makes it easy to quickly service your THM unit and put it back into operation.

TAILORED TO YOUR NEEDS

The THM blasting units are available in a range of configurations, specifically adjusted to your needs and the size of your workpieces. Further fine adjustments can also be made thanks to the variable processing parameters, such as the belt speed, discharge velocities and blasting medium flow rate.

To ensure the optimal result for every application we have completed our range of products with our smallest THM 300/1 and our largest THM 900/4/E.

THE BENEFITS AT A GLANCE

- Processes both bulk material and individual parts with different shapes and sizes

- Manual or automatic workpiece feeding

- Controllable processing parameters: throughput times, discharge velocities, optional blasting medium flow rate regulation

- Two turbines with 7.5 to 22 kW of power, depending on the machine type (can be upgraded to up to six turbines depending on configuration)

- Special turbines for aluminium blasting medium

- Easy-to-reach wear zones for quick maintenance

- Customised filter systems

- Wide range of loading and unloading mechanisms, such as lifting and tipping units, vibrating hoppers, rotating buffer tables and refilling systems

- Belt rods made from either polyurethane or manganese steel

TECHNICAL SPECIFICATIONS

| HM300/1 | THM300/2 | THM400/2 | THM400/2/E | THM500 | THM700 | THM900 | |

|---|---|---|---|---|---|---|---|

| Operating tunnel diameter (mm) | 300 | 300 | 400 | 400 | 500 | 700 | 900 |

| Quantity of chambers (pcs.) | 1 | 2 | 2 | 3 | 3 | 3 | 3 |

| Quantity of rods (pcs.) | 43 | 43 | 53 | 53 | 63 | 76 | 92 |

| Turbines quantity (pcs.) | 1 | 2 | 2 | 2 - 3 | 2 - 3 | 3 - 4 | 4 |

| Drive with FI | Direct | Direct | Direct | Direct | Direct | Direct | Direct |

| Power turbines (kW) | 7.5 | 7.5 | 7.5 | 7.5 - 15 | 7.5 - 22 | 11 - 15 | 15 |

| Air volume dust collector (Bm³/h) | 2,000 | 2,500 | 3,000 | 3,000 / 5,000 | 3,000 / 5,000 | 7,500 | 7,500 |

| Smallest parts size, diagonally (mm) | 20 | 25 | 25 | 25 | 25 | 25 | 25 |

| Minimum thickness (mm) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Largest parts size length (mm) | 150 | 200 | 200 | 650 | 650 | 650 | 800 |

| Diameter (mm) | 100 | 100 | 120 | 250 | 350 | 450 | 450 |

| - Special lenghts of infeed channel upon request | |||||||

| - THM special machines available upon request | |||||||

MEASUREMENT TABLE THM

| THM300/1 | THM300/2 | THM400/2 | THM400/2/E | THM500 | THM700 | THM900 | |

|---|---|---|---|---|---|---|---|

| L | 2,700 | 4,140 | 4,140 | 5,300 | 5,300 | 6,500 | 6,600 |

| B | 1,450 | 1,150 | 1,250 | 1.720 | 1,550 | 2,000 | 2,300 |

| AV | 2,500 | 3,860 | 3,860 | 6,400 | 6,400 | 6,750 | 6,750 |

| H | 4,300 | 4,300 | 4,600 | 5,000 | 4,610 - 7,000 | 4,550 - 5,150 | 4,850 - 5,150 |

| E | 2,400 | 2,250 | 2,400 | 2,550 | 2,550 - 2,650 | 2,220 | 2,520 |

| Dimensions (in mm) | |||||||