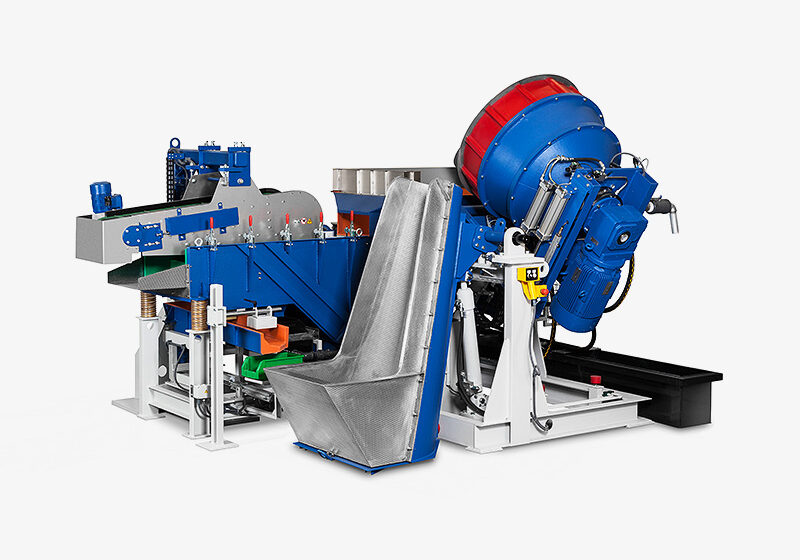

TT…SM CENTRIFUGAL DISC FINISHING UNIT

MASS FINISHING TECHNOLOGY > CENTRIFUGAL DISC FINISHERS

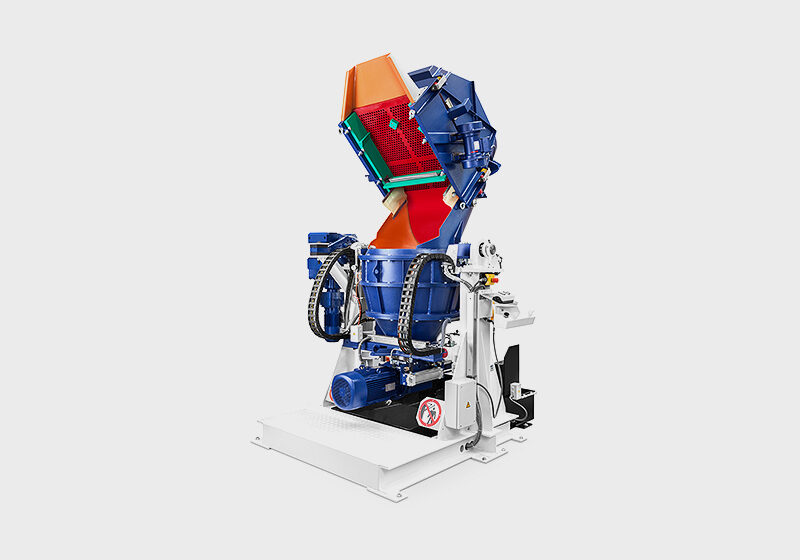

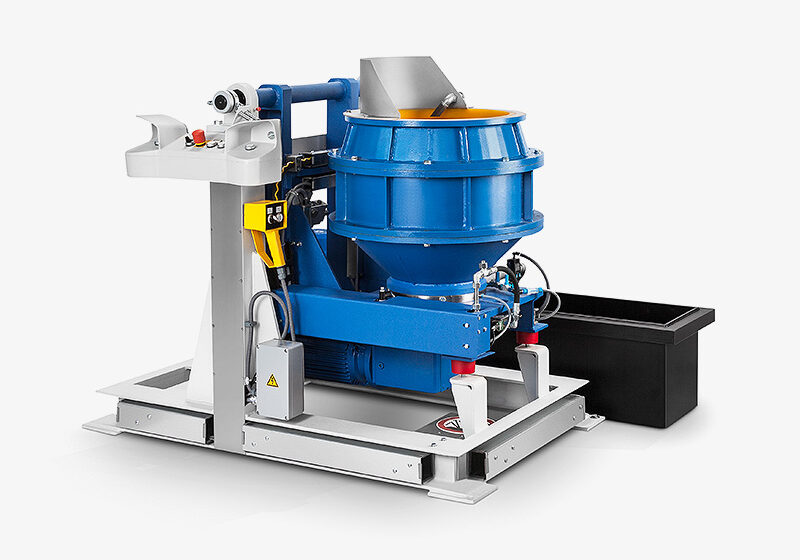

COMPACT AND PIVOTING

Centrifugal disc finishing units from the TT...SM range have an attached screening machine and integrated hopper for abrasive media. After processing the workpieces, the entire unit pivots by 135° to separate the abrasive media and workpiece mass on the screening machine.

SUITABLE FOR HIGH-VALUE WORKPIECES

While the system pivots back into the working position, the abrasive media are conveyed back into the work bowl. This centrifugal disc finishing unit is particularly well suited to processing high-value workpieces, making it a popular choice in the aerospace industry for example.

THE BENEFITS AT A GLANCE

- Compact design saves space

- Cost effective

- Suitable for processing limited quantities

TECHNICAL SPECIFICATIONS

| Machine type | TT 90-SM | TT 140-SM |

|---|---|---|

| Gross volume (l) | 90 | 140 |

| Usable volume* (l) | 8–60 | 14–100 |

| Work bowl material | Steel / Polyurethane | |

| Drive mode | electric | |

| Spinner power kW | 4 | 11 |

| Speed (RPM) | 213 | 178 |

| * Part geometry, material and delicacy are important for the determination of the media/workpiece ratio. | ||

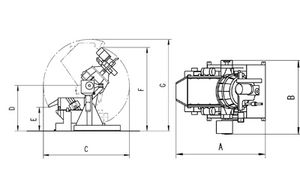

MEASUREMENT TABLE

| A | B | C | D | E | F | G | |

|---|---|---|---|---|---|---|---|

| TT 90-SM | 2350 | 1580 | 2630 | 1350 | 650 | 2350 | 2780 |

| TT 140-SM | 2350 | 1860 | 2800 | 1480 | 770 | 2710 | 3000 |

| Dimensions in mm | |||||||