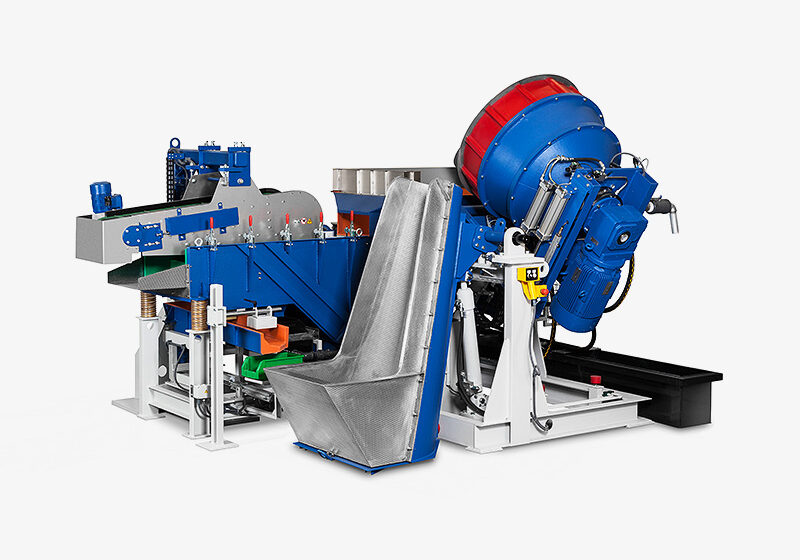

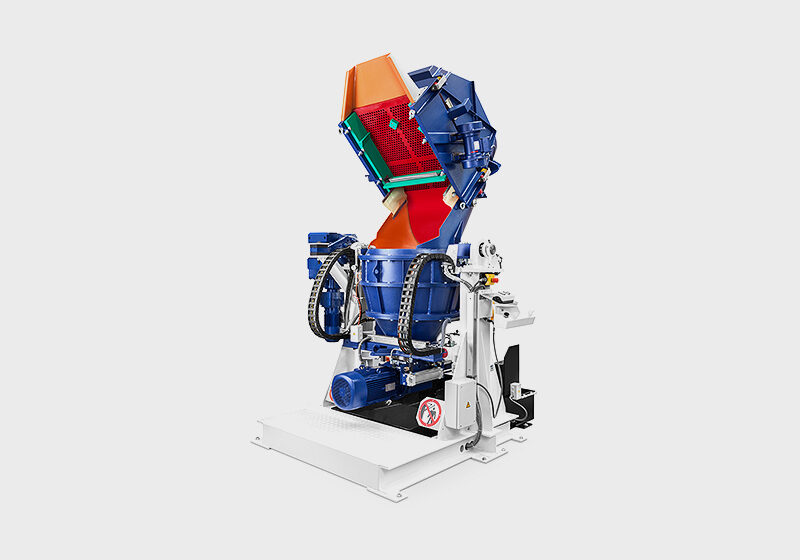

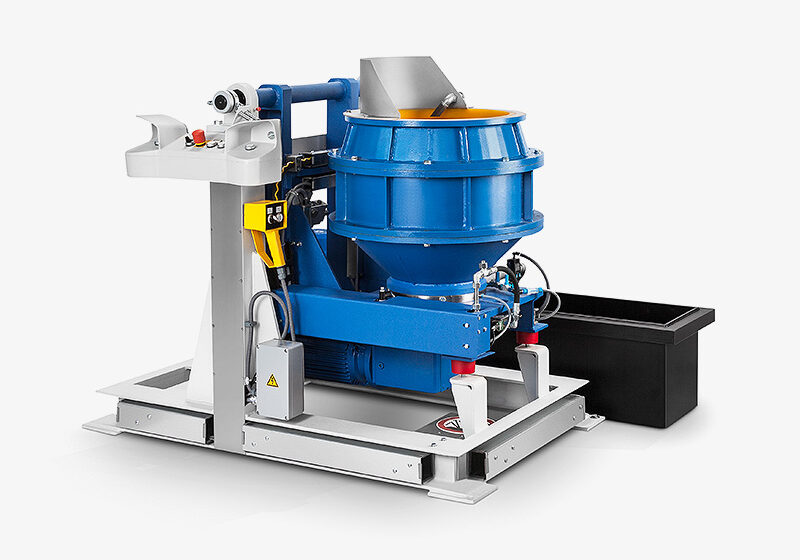

M-TMD

MASS FINISHING TECHNOLOGY > DRAG FINISHING EQUIPMENT

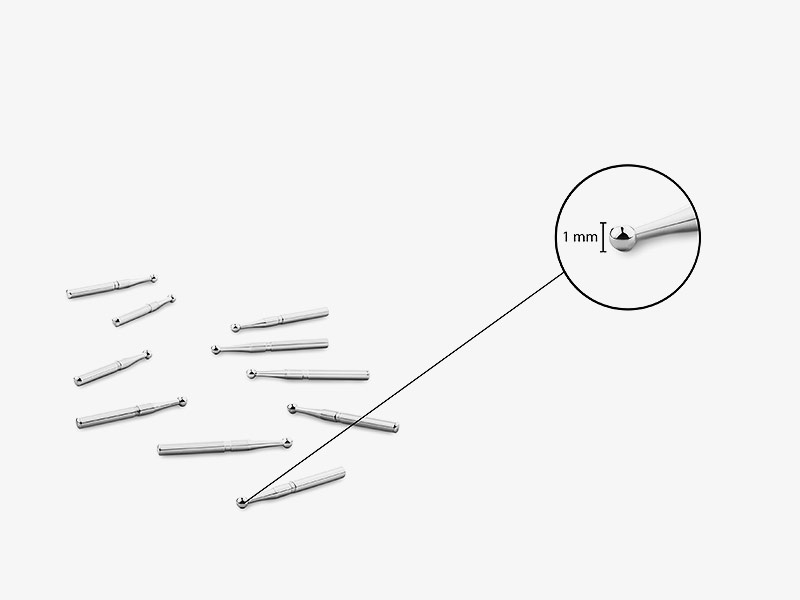

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER

Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement.

Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results.

APPLICATIONS

- Orthopedic implants (medical engineering)

- Turbine blades (for airplanes as well stationary turbines)

- Precision components, for example, for pumps and compressors

- Work pieces made from tungsten carbide and other hard metals

- Fan wheels for turbo chargers (automotive industry)

- Sintered components, etc.

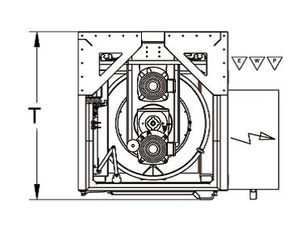

TECHNICAL SPECIFICATIONS

|

machine |

M-TMD 4M |

M-TMD 6M |

|

Dimensions (L x W x H) |

||

|

- with control panel |

1360 x 1610 x 2450 mm |

1680 x 2010 x 2620 mm |

|

Machine frame |

||

|

- Robust welding construction |

X |

X |

|

- Hydraulic aggregate for UP/DOWN movement of the work unit |

X |

X |

|

Work bowl for wet application |

||

|

- work bowl lining with sprayed PU |

X |

X |

|

- Top of bowl |

ca. 840 mm |

ca. 840 mm |

|

- Depth of bowl |

440 mm |

440mm |

|

- Inner diameter |

840 mm |

1080 mm |

|

- Vibratory motor for mixing |

1,35 KW |

1,35 KW |

|

- Lifting station |

X |

X |

|

- volume |

240 litre |

430 litre |

|

Dosing station for wet application |

||

|

- for water and compound |

X |

X |

|

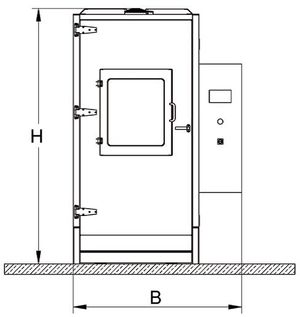

Control panel |

||

|

- Eaton Touchscreen 10“ for control of all functions |

X |

X |

|

- Beacon light as optical alarm |

X |

X |

|

Work carrousel |

||

|

- Drive of carrousel via gear motor |

X |

X |

|

- Power |

4 KW |

7,5 KW |

|

- Infinite RPM adjustment, variable from / to |

5 - 80 rpm |

5 - 80 rpm |

|

- sense of rotation: right / left run |

X |

X |

|

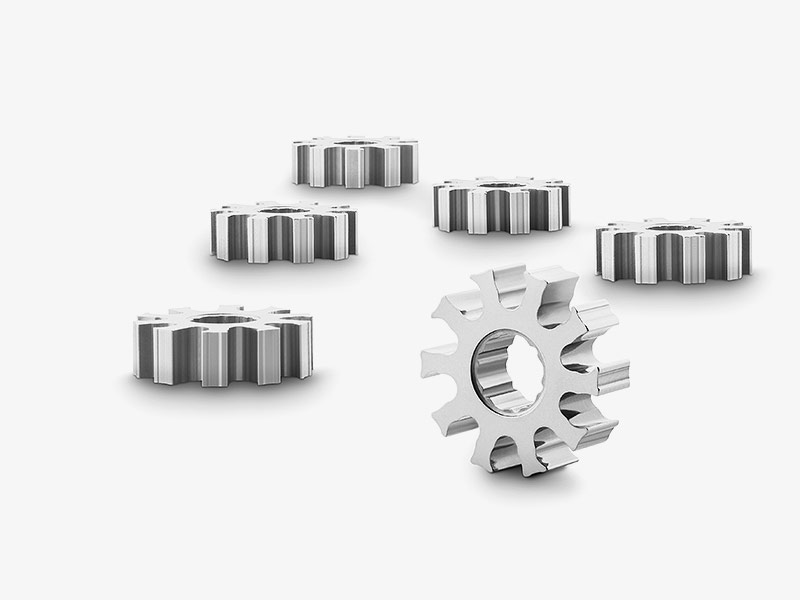

Work stations |

||

|

- Work stations with drive independent from the carrousel |

4 pc |

6 pc |

|

- Power |

3 kW |

3 KW |

|

- Change of rotational direction, at choice right / left |

X |

X |

|

- Infinite RPM adjustment from / to |

5 - 80 rpm |

5 - 80 rpm |

|

- Supply of work piece fixtures |

by customer or at extra price |

by customer or at extra price |

|

- pitch point |

350 mm |

670 mm |

|

Protective cabin |

||

|

- Acc. to guideline 2006 / 42 / EG |

X |

X |

|

- Front door with manually activated operating window for change of parts fixture |

X |

X |

|

- Door and operating window locked electrically |

X |

X |

|

Options |

||

|

- Mono spindle with inclined position 0 - 25° in 5° steps |

o |

o |

|

- Triple spindle with inclined position 0 - 25° in 5° steps, transmission ratio 1 : 1.7 |

o |

o |

|

- Work bowl for dry application |

o |

o |

|

Technical changes reserved |

||

|

X = standard |

||

|

o = additonal price |