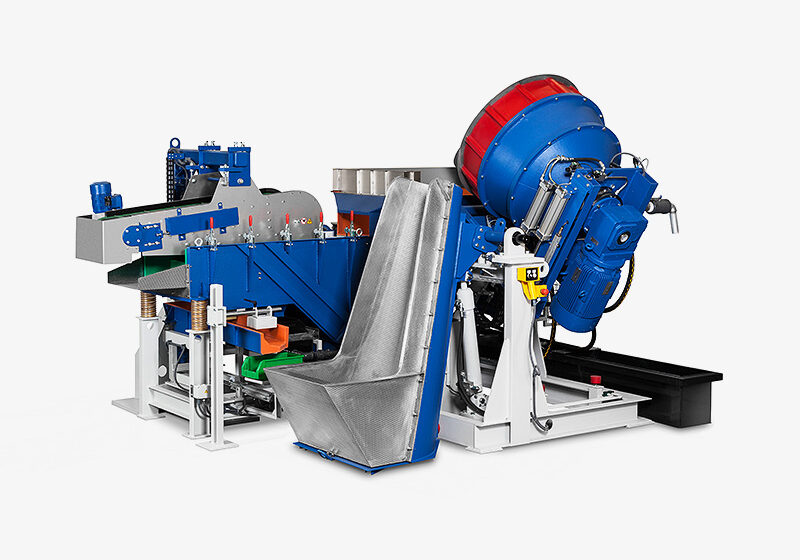

ROTATING BARREL FINISHERS

MASS FINISHING TECHNOLOGY > DRUMS AND ROTATING BARRELS

EXTREMELY GENTLE PROCESSING

Rotating barrels offer a cost-effective and technically ideal solution, particularly when processing small parts in medium batches. This helps you get fine surfaces with neatly rounded workpiece edges, thanks also to the relatively long processing times. Trowal rotating barrels are also excellent for fine finishing and polishing.

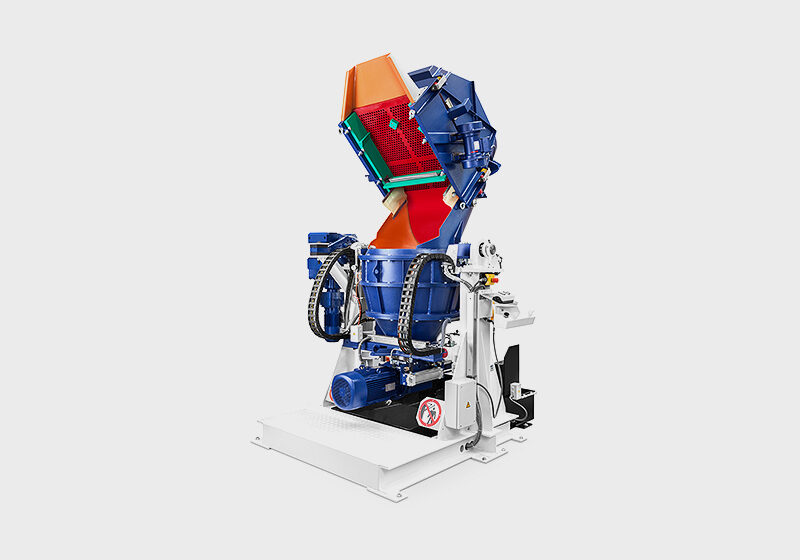

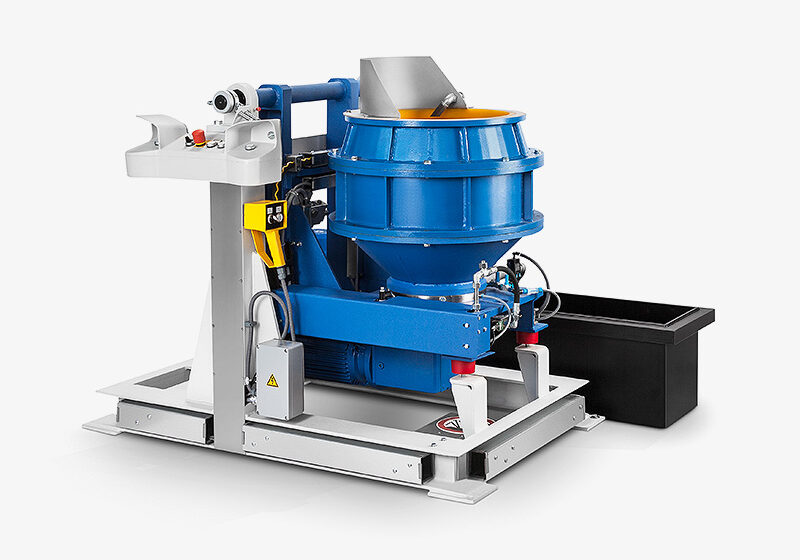

SOPHISTICATED TECHNOLOGY

The barrel body is an octagonal, welded, biconal structure. It generates a triple sliding action in the mass of abrasive media with the workpieces to be processed. The lining consists of tear-proof rubber or PU, with the tight-sealing safety cover made of polyurethane.

BARREL BODY WITH LIFTING AND LOWERING DEVICE

The automatic lifting and lowering device lets you quickly feed and empty the barrel body. This is a major advantage, especially when processing times are short and when you are operating multiple rotating barrels.

SPECIAL EQUIPMENT

Alongside the standard equipment, you can choose from the following special equipment:

- Nipple and a rotating Walther quick-action coupling

- Rinsing unit with screening cover and quick-clamp device

- Full speed adjustment via frequency converter

THE BENEFITS AT A GLANCE

- Available with optional rubber lining

- Trowalize large and sensitive parts

- Powerful conventional imbalance motors

- Ideal for ball polishing and pressure deburring

TECHNICAL SPECIFICATIONS

|

A 65 |

A 110 |

A 150 |

A 220 |

|

|

Usable volume* (l) |

30 |

50 |

70 |

100 |

|

Lining thickness (mm) |

8 |

|||

|

Power (kW) |

1,5 |

1,5 |

||

|

Rotational speed (RPM) |

2-30 |

2-30 |

||

|

Weight (kg) |

425 |

445 |

460 |

480 |

|

Workpiece dimensions * (mm)** |

120 |

200 |

200 |

250 |

|

* Ratio of media to component normally 3:1, i.e. 3 parts media and 1 part component |

||||

|

** Workpiece dimensions limited by barrel opening. Rotating barrels are mainly used for gentle processing of small workpieces. |

||||